Bendpak HDSO-14AX 14,000-Lb. Capacity Open Front Extended Alignment Lift

Bendpak HDSO-14AX 14,000-Lb. Capacity Open Front Extended Alignment Lift

Open-Front Design and 14,000 Lbs. of Might

The HDSO14AX is a 14,000-lb. capacity open-front alignment lift. The “open” design makes it easier to access the front turn plates and undercarriage. Our alignment system features front turn plates and rear slip plates built right into the runways. The wheels always respond to your adjustments with no resistance or hassle. This car lift is available with optional drive-thru ramps, drip trays and rolling jacks.

Features

- 14,000-lb. lifting capacity.

- CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN-1493.

- Heavy-duty turn plates and integrated rear slip-plates included.

- Multi-position turn plate pockets.

- Automatic leveling system.

- Multiple auto-leveling locking positions.

- Runways include rail-kit for optional accessories.

- Electric / hydraulic power system.

- Single hydraulic cylinder mounted underneath runway.

- Fully enclosed lifting cables, safety locks, and sheaves.

- Internal “Anti-Sway” UHMW slider blocks in each column.

- Features oversize sheaves and heavy-duty 1/2” aircraft cable.

- Rugged 1-3/8” roller axles and oversize self-lubricating cable sheaves.

- Multi-position safety locks in each column with push-button safety release.

- Runways adjust for different tread widths and feature non-skid surface.

- Optional 7,000-lb. capacity bridge jacks available (Model RJ?7) 14,000-lb. lifting capacity.

Specifications

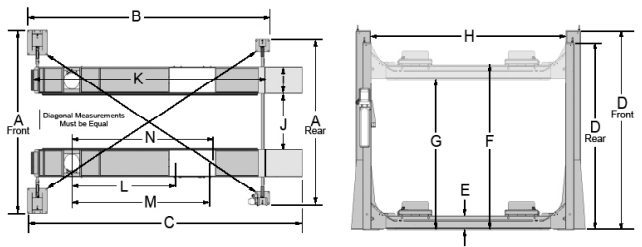

| Model | HDSO-14AX |

| Lifting Capacity | 14,000 lbs / 6350 kg |

| A - Overall Width / Front | 143.25 in. / 3638 mm |

| A - Overall Width / Rear | 130 in. / 3304 mm |

| B - Outside Length | 215.5 in. / 5472 mm |

| C - Overall Length | 244.5 in. / 6209 mm |

| D - Height of Columns / Front (*) | 103.25 in. / 2623 mm max. |

| D - Height of Columns / Rear(*) | 92 in. / 2338 mm max. |

| E - Min. Runway Height | 7.75 in. / 196 mm |

| F - Max. Rise | 77.5 in. / 1970 mm |

| G - Max Lifting Height | 70.75 in. / 1797 mm |

| H - Width Between Columns / Front | 123 in. / 3127 mm |

| H - Width Between Columns / Rear | 120 in. / 3050 mm |

| I - Runway Width | 20.5 in. / 520 mm |

| J - Width Between Runways(**) | 45 in. / 1146 mm |

| K - Length of Runways | 199 in. / 5054 mm |

| L - Min. 4- Wheel Alignment (***) | 89 in. / 2261 mm |

| M - Max 4 Wheel Alignment (***) | 156 in. / 3962 mm |

| N - Max 2 Wheel Alignment (***) | 175 in. / 4445 mm |

| Min. Wheelbase @ Rated Capacity | 140 in. / 3556 mm |

| Min. Wheelbase 75% Rated Capacity | 120 in. / 3048 mm |

| Min. Wheelbase 50% Rated Capacity | 100 in. / 2540 mm |

| Min. Wheelbase 75% Rated Capacity | 80 in. / 2032 mm |

| Locking Positions | 13 |

| Lock Spacing | Every 4” / 102 mm |

| Lifting Time | 60 Seconds |

| Standard Motor | 220 VAC / 60Hz 1 Ph. |

Emission sound pressure at Operator Position < 70 dB(A)

* Safety Ladder Adjustment bolt may add up to 3.75 in. / 95 mm to overall column height.

** This dimension may be limited with the addition of rolling jacks.

*** For CE compliant countries see errata sheet included with control panel.

*The design, material and specifications are subject to change without notice

Optional Accessories (*Sold separately)

|

|

|

|

|||

| WSA-100 | DP-30 | Rolling Jacks | Airline Kit |

Downloads