Automotive Paint Booth Guide

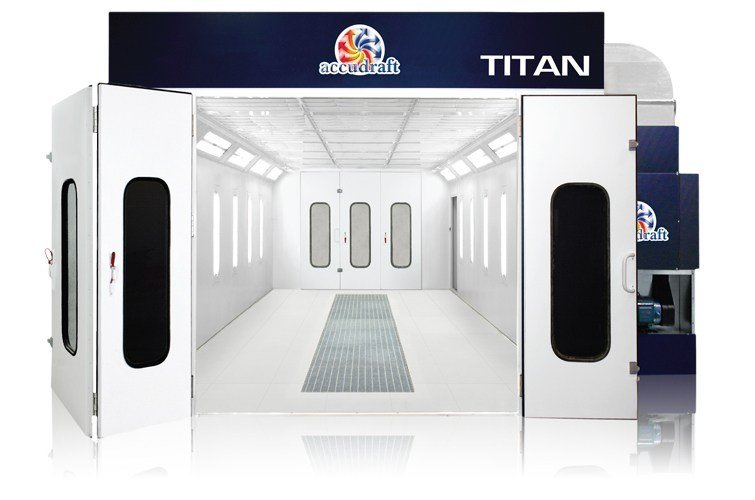

Automotive paint booths, most commonly known as spray booths, are pressure-controlled and closed environments that are used to paint vehicles from the smallest cars to the largest trucks. These booths can be found in most body shops these days and are usually fitted with different ventilation systems and motors to ensure an even paint job and to maintain a stable temperature and aid in reducing humidity levels in some instances.

The following is a comprehensive automotive paint booth guide created by our specialists here at JMC Automotive Equipment that will offer a deeper insight into the different types of spray booths available on the market, as well as into some of the most important features and functions that make them stand out from the rest.

A Closer Look at the Different Types of Automotive Spray Booths and Their Individual Benefits

There are several different types of automotive paint booths that one can find in an auto body shop, and each type has its own advantages and disadvantages. These paint spray booths can be classified according to their features or their overall design – while some of them are open, others are fully enclosed. However, the manner in which the air is filtered, pressurized and then re-directed is yet another factor that makes a difference, as some booths are pressurized while others are non-pressurized. The latter, draw their air through the special inlet area (which comes with a filter attached to it), and after that the exhaust fan simply exhausts the air through ducting leading outside of the building.

In spite of the fact that there are many different varieties of booths, they all have the same mechanism of action: the booths draw fresh air inside them and then they rely on their exhaust fans or Air Make Up units and exhaust fans to supply airflow for the booth. For the best results, the air that is used by the paint booth must be as clean as possible in order to prevent contaminants from interfering with the spraying process, as they might impact the quality of the paint and lead to uneven and sometimes disastrous results.

What is a Fully Enclosed Automotive Paint Booths?

Fully enclosed paint booths are the most commonly used mainly because they provide a cleaner painting environment. They are available as negative pressure or positive pressure environments. Negative pressure booths are only using the exhaust fan to pull air into the booth from the ambient air outside of the booth cabin and positive pressure booths are pulling air into the booth through and Air Make Up unit. A booth with an Air Make up unit comes with an inlet, where air is drawn which pushes more air into the cabin than the exhaust is taking out, providing a pressurized environment and it also can be used with heat for cold days as well as provide the opportunity for baking or curing the painted surfaces for quickly.

One of the most notable benefits of the fully enclosed car paint booths is that unlike the open-front ones, these booths significantly reduce the amount of dirt, dust and other particles that can affect the painting process, due to the intake filter that is installed inside the inlet areas of the booth. The purpose of this filter is to keep dirt and debris outside and to ensure a high air quality.

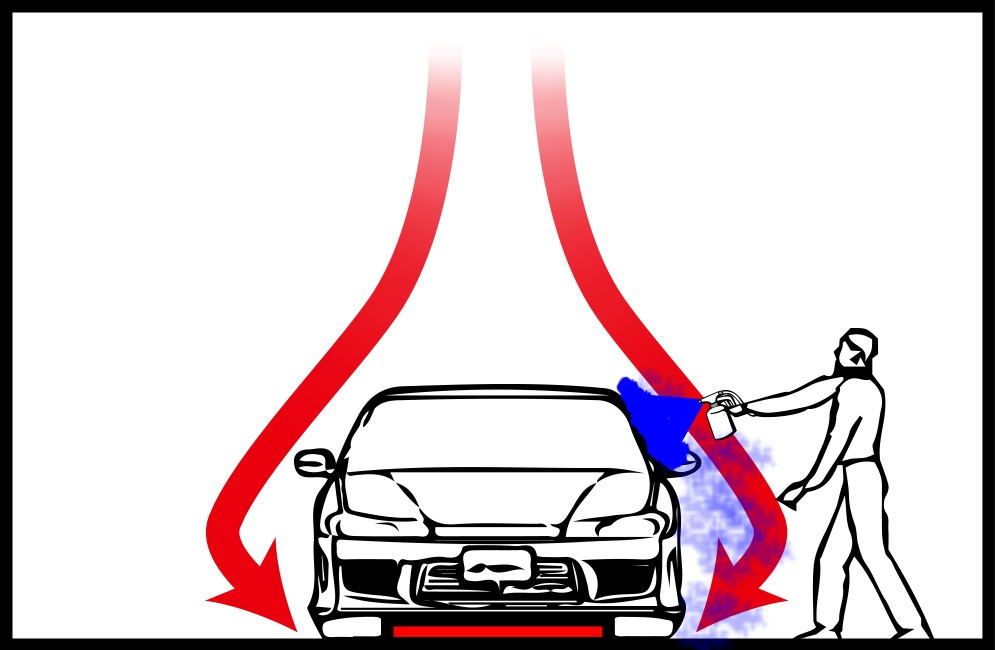

1. Downdraft Paint Booths

The downdraft booth are among the most advanced ones and they come with different price tags – you can purchase them with their default features or you can opt for a modified downdraft booth. Down Draft booths typically are enclosed booths that also have intake filters and they most often are used with an Air Make Up unit providing clean fresh air in a slightly positive pressure environment. This booth is known for providing the cleanest environments for painting vehicles. In terms of Good, Better, Best, this booth would be characterized as Best. Down Draft Booths with Air Make Up units tend to be more costly than other versions but they do provide a very good Return on Investment. They are commonly found in large or high production shops.

The unique air flow characteristics of the downdraft booths have made them very sought-after these days, and they are commonly used both for large and for small vehicles. As a matter of fact, this type of spray booth is the most commonly used one for industrial applications (especially for trucks), due to the generous ceiling filter that allows more air to be exhausted through the pit system located in the floor of the booth.

2. Semi Down Draft Paint Booths

The Semi Down Draft that has the exhaust which is typically located at the end of the entire structure with the airflow going down over the vehicle at a 45 degree angle for good air for 2/3’s of the booth and OK air by the entry doors. The air is introduced through the front of the booth through a plenum and the air flows throughout the booth creating a diagonal draft pattern and pushing overspray away from the painter and the car being worked on. This booth can also house an air make up unit heating and baking cars so that jobs are done much faster with this booth.

The semi down draft paint booth is one of the most popular out in the market mainly because of price and because you don't need to do any concrete work and or raised the booth for a basement.

3. The Crossdraft Paint Booths

The crossdraftbooths manipulate the movement of the air in a totally different way. In a nutshell, a crossflow booth is designed to make the air move through the booth, all the way from one end of the structure to the other one, thus the name of “cross flow”. This type of structure has literally been used for decades, and most of them are non-pressurized. When pressurized the quality of the air is higher when moving across the booth.

Crossdraft Booth Air Flow

Even so, it is not uncommon for some body shops to use non-pressurized crossdraft booths as they have their advantages. You cannot control the air temperature within a non-pressurized structure of this kind (unlike it happens in a pressurized cabin). This type of booth is still able to deliver good paint jobs, but will require more effort than the booths listed above. Also, the overall cleanliness and quality of the air can vary from one type of crossdraft paint booth to another depending on the filtered area or size of both the intake air and the exhaust and their relative locations – either way, the pressurized structures offers the user far more control over the entire process, and this is the reason why they are to be preferred over the non-pressurized ones.

What Are The Benefits Of Using A High-Quality Automotive Paint Booth?

The first and perhaps the most important advantage of relying on a high-end car paint booth is the fact that the body shop using it can deliver work of an impeccable quality. At the same time, using a specialized designed with auxiliary controls that allow you to better control the booth environment significantly increases the production levels and it allows you to save a lot of time in the refinish process. The showroom-like quality finish of the cars coupled with the advanced technology embedded in these spray booths are generally the main reasons why many body shop owners choose to invest their money in such a structure nowadays.

The auto collision repair service has advanced greatly over the past several years, and so has the technology in the field. What every body shop owner wants is to deliver the highest number of quality paint jobs within the shortest period of time, and this is precisely why it is extremely important to choose your spray booth for your facility carefully. Call us up at 800-562-4791 to discuss your needs and so we can point you in the right direction when choosing your Automotive Paint Booth.

If you like to get more information about our paint booths please fill this out and we will get back to your right away.