Five essential tools to successfully running an automotive repair shop

Posted by JMC Team on 23rd Feb 2023

Running a successful auto repair shop requires the use of proper tools. The impact of tool quality on your company's effectiveness, productivity, and work quality grows with tool quality. However, equipping your auto repair shop is a long-term project, and considering the best tools when you first start is critical to meeting your customers' daily needs.

This article will go over the ten most important tools for running an automotive repair shop. These tools are often overlooked, but they can make a significant difference in your auto repair shop's day-to-day operations.

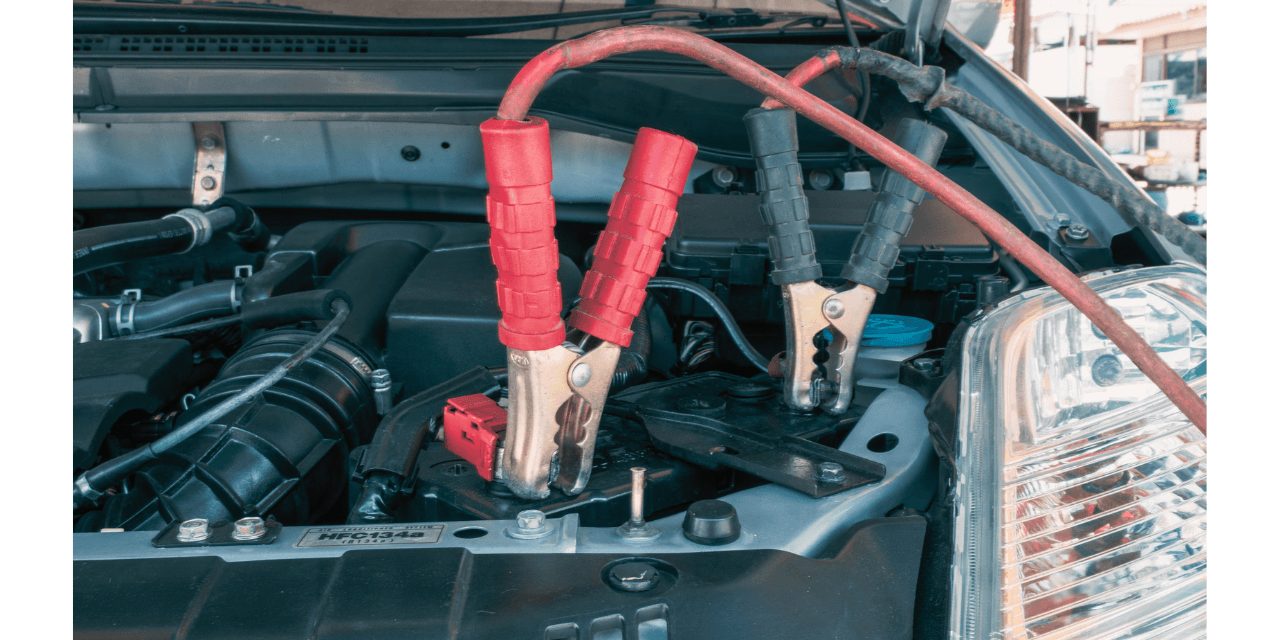

1. Battery chargers

A battery charger is an essential tool for any automotive repair shop. It is used to recharge the batteries in cars, trucks, and other vehicles. Battery chargers come in many shapes and sizes, each designed for a specific type of battery.

A trickle charger is a low-amperage charger that is used to maintain the charge in a battery over a long period of time. A fast charger is a high-amperage charger that can quickly recharge a battery. A smart charger is a charger that has a microprocessor that monitors the battery's voltage and adjusts the charging rate accordingly.

A Boost HD, also known as a jump starter, is an essential tool for any automotive repair shop. It is used to jump-start a dead battery in a vehicle, and it can also power other electrical devices in the shop. A good Boost HD should have a high peak amp and a long battery life.

When selecting a battery charger, keep the type of battery in mind. A trickle charger is good for maintaining a battery's charge over time, but a fast charger is necessary for quickly recharging a battery.

2. Air Hammer

An air hammer is a versatile tool. It can assist you with a variety of tasks in your automotive repair shop, such as removing or installing exhaust systems, suspension components, and stubbornly rusted or seized parts. A good air hammer should have several chisel attachments, be powerful, and be ergonomic for ease of use.

Hammers come in a variety of shapes and sizes, each designed for a specific task. A ball-peen hammer is a common type of hammer with rounded and flat ends. The rounded end is used to shape metal, while the flat end is used to strike objects. Sledgehammers are larger, heavier hammers that are used for heavy-duty tasks such as breaking concrete or driving fence posts. Dead blow hammers are hammers with a hollow head filled with sand or lead shot, which reduces bounceback and vibration.

When selecting an air hammer, keep the task at hand in mind. A ball-peen hammer may be adequate for light-duty tasks, but a sledgehammer will be required for heavy-duty work. For tasks that require precision, a dead-blow hammer is appropriate. It reduces the risk of damaging the surrounding area.

3. Air drills

An air drill is an essential tool for any mechanic's shop. It is used for drilling holes in metal, plastic, and other materials. Compressed air powers air drills, which are designed for heavy-duty tasks.

An angle drill is a power tool that allows a mechanic to reach tight spaces when working on a vehicle. It can be used for drilling, screwdriving, and other tasks. A good angled drill should have a powerful motor, variable speed control, and be comfortable to hold.

Air drills come in many shapes and sizes, each designed for a specific task. A standard air drill has a chuck that can hold drill bits up to a certain size. A right-angle drill is designed to fit into tight spaces and can be used for tasks that require a smaller drill bit. A pistol-grip drill has a more ergonomic design that allows the user to grip the drill with their entire hand.

When choosing an air drill, it is important to consider the task at hand. A standard air drill is right for light-duty tasks, but a right-angle drill or pistol-grip drill may be necessary for tasks that require precision or accessibility.

4. Impact Wrenches

Any auto repair shop needs impact wrenches as a basic tool. They make it simple and quick for mechanics to take out and replace bolts and nuts on cars. Impact wrenches are crucial for vehicle repair shops for a number of reasons, including speed, power, and efficiency.

Impact wrenches allow you to complete repairs faster by quickly removing bolts and nuts. This increases the number of repairs the auto repair shop can handle and speeds up turnaround.

Impact wrenches can produce a lot of torque, which makes it simpler to remove rusty or stuck bolts and nuts. This lessens the technician's labor need and aids in preventing injuries.

When selecting impact wrenches, take into account aspects like size, power, brand, quality, and ergonomics. The impact wrench's size and power should be appropriate for the types of repairs that the shop typically performs. Larger and powerful impact wrenches are often used for heavy-duty repairs, whereas light-duty repairs are preferable.

5.Fan Clutch Wrench

A fan wrench is used to remove and replace the clutch on an engine. A good fan clutch wrench should be easy to grip, made of high-quality materials, and the right size for the job. A fan clutch wrench is a must-have piece of equipment for any auto repair shop because it allows technicians to remove and replace the fan clutch as needed.

When choosing a fan clutch wrench, make sure the shop has the right tool for the job by taking the wrench's size, material quality, and ease of use into account. Because fan clutch nuts come in a variety of sizes, it is critical to select a wrench that will fit the exact size of the nut on the vehicles the company will be working on. A collection of wrenches of various sizes is recommended to ensure that the shop has the correct tool for any car that comes in for service.

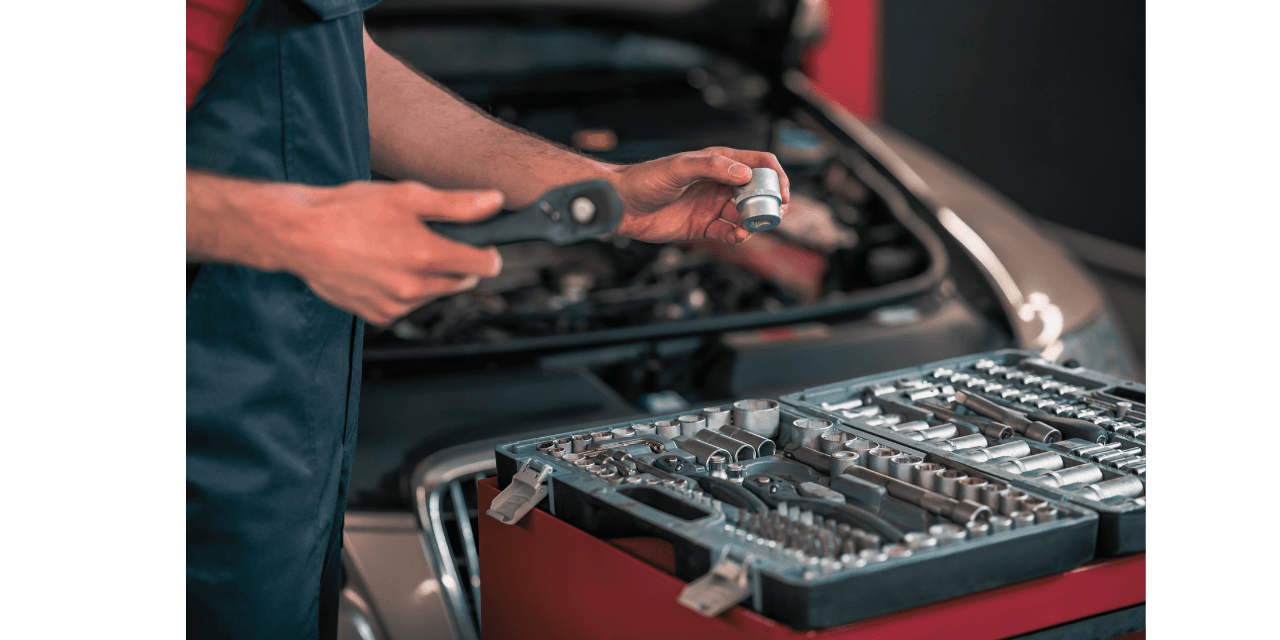

Final thoughts

Finally, running an automotive repair shop requires a wide range of tools, from hand tools to power tools to specialized diagnostic equipment. However, some tools are more essential than others, considering the daily basics. Hammers, air drills, and battery chargers are three essential tools that every mechanic's shop should have. These tools can have an impact on your auto repair shop’s efficiency, productivity, and quality of work.

By investing in high-quality tools, an auto repair shop can work more efficiently and provide high-quality service to their customers. Tools like a socket set, wrench set, screwdriver set, pliers, pry bar set, air compressor, and diagnostic equipment are all required in any automotive repair shop.