Bend It Like A Pro: Variations in Pipe Bending Methods

Posted by Juan E. Chavez on 28th Jul 2018

Pipe bending is one of those basic machining processes that even people in the industry sometimes take for granted. Some metal workers and machine shops will carry sophisticated equipment like Baileigh Plasma Tables, or complete GearWrench sets, yet will have limited tools and knowledge on how to use a three-roll push bending.

Luckily, we’re here to give you a short refresher on pipe bending!

The Basics

Before you start bending pipes, you’ll need to take a good look at the pipes you are using. Pipes carry fluid or air from one part of a machine system to another. Because of the different properties of different types of pipes, the process can be tricky – but also rewarding.

When you’re bending pipes, figure out the exact centerline radius, the outside diameter, and the wall thickness of the material you’re using. This will go a long way in helping you minimize breakage and in ensuring higher quality products.

Aside from their natural properties, pipes also undergo various physical stresses during bending. Things like springback, radial growth, elongation, and wall thinning can happen to pipes during fabrication.

A seasoned metal worker should be familiar with all of these; so, aside from proper equipment, find yourself a trustworthy fabricator – or an old-timey blacksmith, either one works.

The Different Types of Bending

For the uninitiated, pipe bending sounds like a simple process: get metal, bend it. However, there are actually various ways to bend pipes, with different levels of complexity:

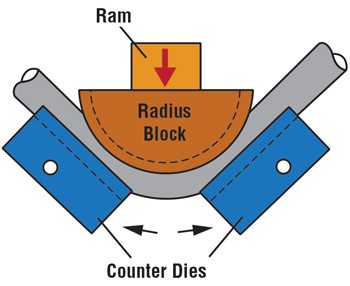

Ram-type Bending is one of the simplest methods of pipe bending. Commonly seen in muffler shops, ram-type bending involves forcing a piece of pipe in between two pivots or rollers using a hydraulically-driven ram. Because of the brute-force approach of ram-type bending, it’s more appropriate for square tubing applications, as the process compresses and deforms the inside bend radius.

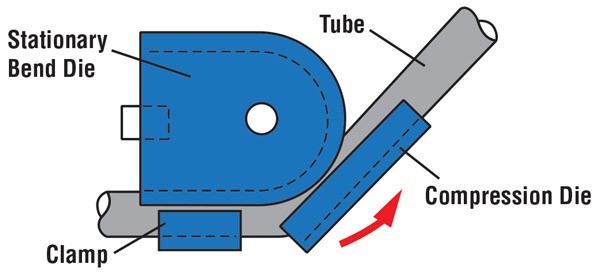

Compression Bending is similar to ram-type bending, in that a piece of pipe or metal is bent around a stationary bend die. This type of bending is often used on workpieces that require symmetrical bends. A machine with two bending heads can produce the symmetrical bends, which is why compression bending is often employed for household products that require multiple, symmetrical bends, like towel racks or door hinges.

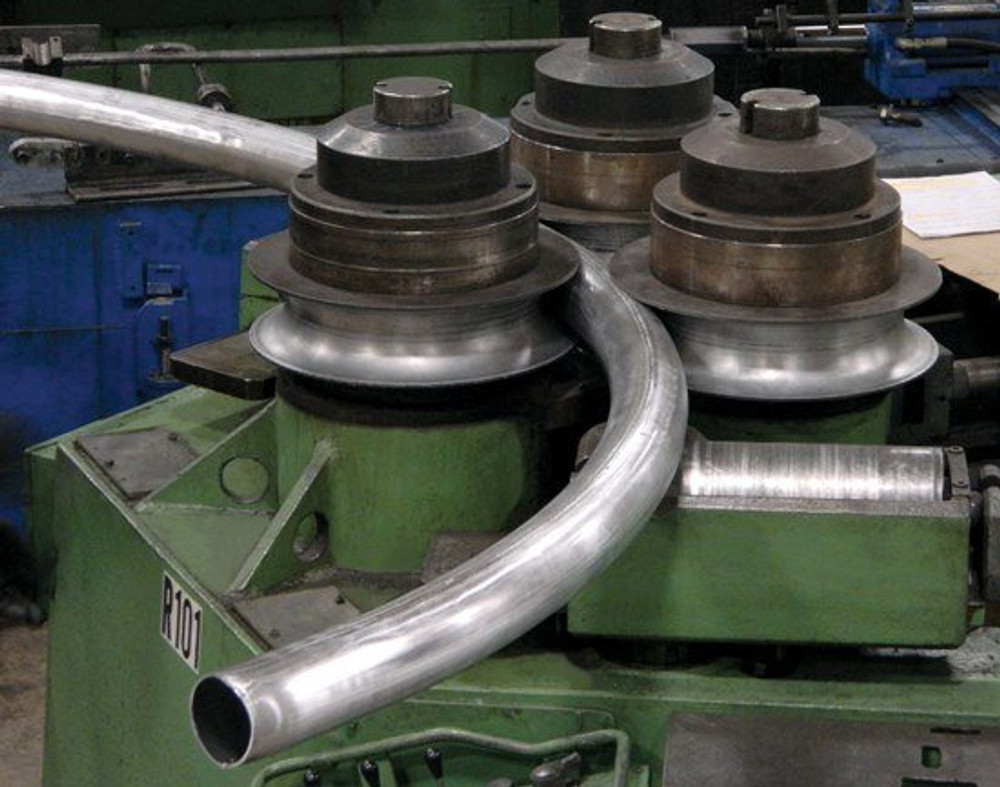

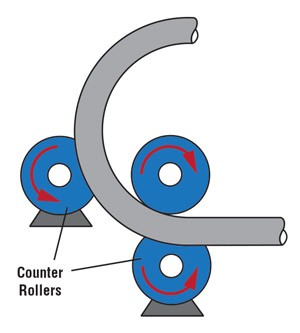

Roll Bending is applied primarily to large workpieces that will be used for construction purposes. Usually, rollers are positioned in a pyramid-type configuration, either vertically or horizontally. A piece of pipe is fed in between the rollers, and the rollers force the pipes into specific bends with a significant radius. Most shops will use roll bending to produce spirals, as the tubes can be lifted after every turn on a tube to produce a coil.

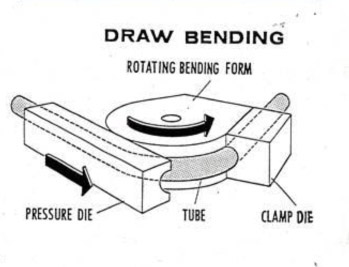

Rotary Draw Bending is the most advanced type of bending, primarily used for pieces that require high precision work. Rotary draw benders accomplish this by holding the straight section of the pipe with a pressure die and then rotating the piece around a round bend die. A mandrel supports the interior of the pipe, while a wiper die prevents wrinkles on the inside radius.

The Tools You Need

Now that you have your pipes, an experienced metal worker, and a rudimentary (hence, the importance of an experienced metal worker) knowledge of the different types of bending processes, it’s time to find the right tools. There is, of course, a wide range of metal bending tools to choose from. However, whatever tool you choose, always go for a machine that has multiple axes of control.

Pipe bending machines usually work with fixed, or stalled, axes. This allows the metal worker to have more control over the whole process.

Under no circumstances are you to bend pipes using your hands. Unless you’re Thor, but we’re guessing you’re not, so please get yourself a professional-grade pipe bending machine. Luckily, we have a large selection of bending machines and other equipment that you’ll need to build your project. JMC Equipment carries whatever you’ll need for your automotive or machine shop, and you can check out our extensive inventory by clicking here .