The debacle of the automotive industry or an opportunity to revive the guild

11th Apr 2025

- Current review of the situation in the industry

- Auto parts tariffs: from the smallest to the largest

- Solutions and recommendations to solve the situation

All of us who are part of and love the automotive industry have the same uncertainty. How will the current U.S. economic and political climate affect our pocketbooks and the growth of our business and the livelihood of our families?

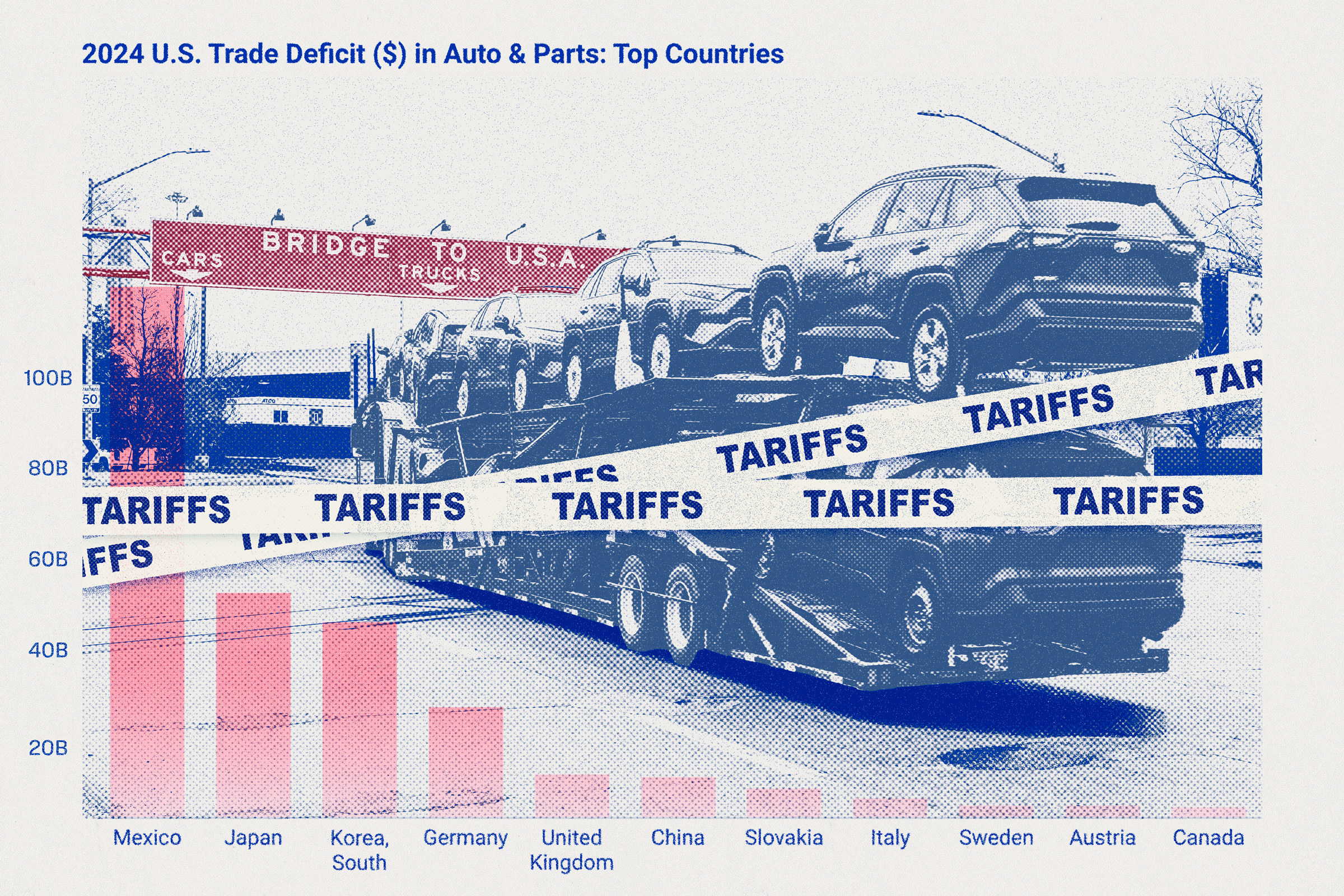

In a context where tariffs affect every import, garages and distributors are facing a crisis. And you wonder, what is happening in the auto parts and equipment market? Is it possible to survive in the automotive world and grow with all the turmoil going on?

The trade war and the rising prices of products imported into the country are increasing the number of auto parts and equipment in the workshops. The instability in the current international trade relations generates a lot of uncertainty in the sector.

The U.S. economy has changed over the last half century; today it is a service economy, not a manufacturing economy. It manufactures fewer and fewer cars, yet automobiles are an important underpinning of the American economy, responsible for growth and job creation, and the operating and economic model is being affected by new decrees.

what is happening in the automotive market?

The Trump administration had set tariffs of 25% on the automotive sector, making every imported vehicle abruptly more expensive. And this is not minor: according to “S&P Global Mobility, almost half of the 16 million new cars sold in 2024 in the U.S., were imports.”

A US$40,000 car would be taxed up to US$10,000 and that cost in the supply chain has to be borne by the buyer.

What do they mean if the tariffs for auto parts are applied?

Most auto parts imported into the U.S. were subject to a 25% tariff, in addition to any existing base tariffs, i.e. they do not qualify for preferential treatment. For example:

- Auto parts imported from countries outside the T-MEC (Mexico, Canada and the U.S.) are expected to be subject to a 25% tariff

- Parts imported from Mexico or Canada that comply with the provisions set forth in the T-MEC may be exempt or have reduced tariffs until the authorities establish a process to impose tariffs only on non-U.S. content.

In other words, the 25% tariff does not automatically apply to every auto part; it depends on where it comes from and whether it meets the criteria for preferential treatment.

By May 3 at the latest, the Trump administration is expected to impose tariffs on imports of auto parts. With the implementation of these new taxes, vehicle production costs will increase, even in U.S. engine plants, due to the high dependence on imported components for domestic car assembly.

Auto parts tariffs: how much are they getting more expensive?

The increase in the cost of auto parts depends on the base price of the part and the proportion of the base price that is made up of imports. Generally, it is possible to estimate a 25% increase in the cost of parts that are affected by the tariff. As an example:

Oil filter:

A base price: US10→Price with tariff approximately US12.50.

Brake discs:

Base price: US50→Price with tariff approximately US62.50.

Electronic control unit (ECU):

Base price: US500→Price with duty approximately US625.

Engine piston:

Base price: US200→Price with duty approximately US250.

It is crucial to understand that these figures are rough estimates and are based on the assumption that each estimate is subject to a 25% tariff. In reality, the impact depends on the 90-day lead time, and the proportion of the component that is imported, active trade agreements and other costs such as transportation, purchases through brokers or intermediaries.

Tariffs to equipment

Recently, several automotive equipment such as car lifts, ATV lifts and tire changers have had a large price increase and this can be attributed to these increases respond to multiple causes that are related between, Here we bring you a price comparison, before and after the tariffs.

Bendpak, in the case of Bendpak has had twice a readjustment, ie an increase of 15% and 20% having changes in all its products, increase in many cases exceeding $ 1,000 dollars. Here we give you a comparison of how it was before and now

- 2 Post Lift 10,000 lb: Previously without tariff cost US$5,895 and now costs US$ 7,495, this lift is ideal for garages, or workshops looking for speed and storage.

- 4 Post Lift of 9,000 Lb: This 4 post car lift, is ideal for people looking for more storage, workshop owners, or users who think about better storing their vehicles, this lift before without tariff cost US$ 5,395 and now goes to cost US$ 6,495.

so there have been many price increases to equipment, what we recommend is to buy for the moment American brands, or at a discount.

Impact of policies and tariffs

Now, if you have a domestic, American car you can have a different range in the market of products and parts, but find something, only companies like Ford, General Motors, Chrysler, manufacture in the U.S., summarizing a little of all this, if you have an American car and you need a part, you may find it cheaper, it is the same as with automotive equipment, if you need a lift, a balancer, a toolbox, or any component or accessory for your equipment, it is likely to be cheaper in Challenger or Tuxedo.

Even if final assembly is done in the U.S. for logistical reasons or to comply with local regulations, a significant portion of your spare parts and critical components continue to be imported. Foreign brands maintain a worldwide manufacturing network.

This allows manufacturers to ensure quality, innovation and rigor in every system integration of their vehicles, regardless of some in the U.S.

If you have a foreign vehicle or are looking for replacement parts from a Japanese, Korean or European brand, it is likely to be more expensive in the marketplace.

In the Japanese companies:

Toyota: Although it has assembly in the USA, for the Camry, Corolla, RAV4, and Highlander, it incorporates spare parts manufactured in Japan and other countries, transmission parts, and engine components. At Toyoya, 44% of vehicles are assembled in the U.S., but 56% are produced in Mexico and Canada.

Honda: Assembles vehicles such as Accord, Civic, CR-V and Odyssey, in American plants, however, key parts such as sensors, control modules, transmission systems are manufactured in Japan. With a 59% share of assembly, Honda has a large share of the U.S. market, but not only that, 41% is assembled in Mexico and Canada

Nissan: Brands such as Altima, Maxima, Rogue or Sentra, are assembled in the U.S., however, the vast majority of parts come from other countries. Nissan has a 46% share of assembly in the U.S., while 54% is produced abroad.

Mazda: Mazda is 100% foreign, and it is known that only 20% of Mazda vehicles sold in the U.S. are made in America.

In Korea

Hyundai: with models such as the Sonata, Elantra, Santa Fe and Tucson, this brand assembles 38% on American soil, while 62% is produced abroad, mainly in South Korea.

Kia: With models such as Sportage, Sorento, Optima and Rio, it is estimated that 35% of cars are assembled in American plants, while 65% are assembled in South Korea.

European Brands

- 43% of BMW models sold in the U.S. are produced in the U.S., however, 57% are manufactured overseas, largely in Germany and other global production centers.2. 36-37% of Mercedes-Benz sold in the U.S. are assembled in the United States. The remainder, 63-64%, are produced outside the U.S.3. Almost no Audi vehicles sold in the U.S. are produced on U.S. soil; virtually 0% are made in the U.S. 100% are produced in Europe or other production centers.4. 30% to 35% of Volvo vehicles sold in the U.S. are assembled in America, while the remaining 65-70% are produced outside the U.S.

When purchasing parts for your vehicle, keep in mind that even though the tariffs have been paused, the price increase is still in effect for many workshops and stores, since the vast majority are prepared, we recommend ordering your parts or accessories in less expensive parts, look for new and inexpensive suppliers.

Should you invest in equipment now?

Many people are wondering whether now is the right time to invest in equipment. Whether it is for the workshop or the garage, there has been a marked increase in the price of equipment from well-known brands in the industry. For example, lifts that used to cost US$5,000 are now priced at around US$8,000, and the same trend is seen in other equipment; this increase is due to multiple factors, such as production, assembly and shipping.

At JMC, specialists in automotive equipment, we recommend opting for American-made equipment and advanced technology, since they provide efficiency and agility when performing work, both in professional workshops and in private garages. Equipment such as balancers and tire changers, among others, have become essential tools to speed up and optimize processes, especially in a context of labor shortage. In addition, we advise you on the purchase of native brands; for example, Challenger is an American brand that maintains stable prices, and Tuxedo offers promotions of up to 10% discount on products with prices that do not exceed US$4,000.

Here at JMC, we not only guide you to make the right decision on whether to buy now or wait, but we also help you evaluate the brand, its discounts, delivery times and the competitive advantage the equipment gives you whether it is made in the USA or imported.