RGI Heater and AMU

Available from 1 million to 3.5 million BTU burners

- Easy Installation and setup

- Superior finishing due to reduced air particles

- Reduction in total Energy cost

- Decreased cold air permeation

- Increased production with a faster dry time

Construction

Pre-painted (White In & Out) Panels 16 (GA) Galvanized / metal

|

|

|

|

- ETL Listed

- Formed G-90 Galvanized base < 10,000 CFM

- Primed welded structural steel base > 10,000 CFM

- G-90 Galvanized Casing

- Single-wall access doors

- Internally mounted motor, burner, and controls

- Pre-piped, pre-wired, and factory tested

- Sectioned units may require field assembly, wiring, and piping

- Lifting Provisions

- Vertical units have additional features

- Built-in filter sections

- Built-in 36" stand

- Ground-level electric and manifold service access

Fan & Motor

- DWDI forward curve industrial type blower(s)

- Solid-turned ground and polished shaft

- Self-aligning bearings

- Premium E ODP blower motor with 1.15 service factor

- Motor starter & overload protection

- Adjustable motor base

- Variable pitch drive up to 30 HP (Except when VFD is utilized)

RGI Control Panel

All RGI heaters are equipped with technology which gives you full control of your heater's functions and performance. The touch-screen monitor comes with everything from Fast Dry cure mode to even the more economical "prep" mode. Power and control are right at your fingertips.

- Non-fused door interlocked disconnect switch

- Discharge air temperature control, with remote set point & summer-off-winter selector switch

- Auxiliary contacts for exhaust fan interlock

- Control voltage transformer

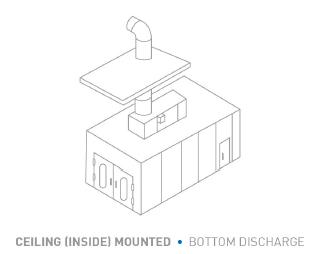

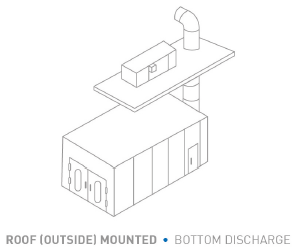

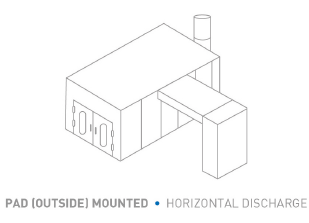

Configurations

The standard configuration is to mount vertically next to the booth. Configuration options include: Vertical or suspended, Indoor or outdoor, roof (booth roof or building roof, please specify), or stand mounted.

|

|

|

Features

- ETL Listed to Z83.4 / CSA 3.7 | Non-Recirculating

- ETL Listed to Z83.18 | Recirculating

- 1,200 - 120,000 CFM | Single Speed

- 4,000 - 120,000 CFM | Variable Air Volume

- Multiple Fan Type Options

- Multiple Accessory and Control Options

Custom Configurations and Dimension TRU-BLUE | REPAIT AIR All RGI heater units are built with variable air volume design. The supply air volume is adjusted by a VFD (variable frequency drive) which allows each unit to respond to changing exhaust loads. Many applications can control building pressure as exhaust varies. The electrical power consumption drops on a cubed ratio to blower speed and gas consumption, reducing operational costs. *Maximum 100°F temp rise for Natural Gas.

Heating Specifications

1,000,000 BTU heater:

- LOWNOX (Optional)

- 12,000-15,000 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 7.5 Hp 3ph/1ph Intake Motor

1,000,000 DD BTU Heater (DownDraft) *(DOWN DRAFT (DD) HEATERS ARE 10HP MOTORS TO COMPENSATE FOR INCREASE IN AIRFLOW/BASEMENT VOLUME)

- LOWNOX (Optional)

- 12,000-15,000 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 10Hp 3ph/1ph Intake Motor

1,500,000 BTU heater

- 18,000-20,000 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 10Hp 3ph/1ph Intake Motor

2,000,000 BTU heater

- 19,000-21,000 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 2 - 3ph/1ph Intake Motor

2,500,000 BTU heater

- 21,500-23,500 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 2 - 3ph/1ph Intake Motor

- 24,000-28,000 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 2 - 3ph/1ph Intake Motor

- 31,000-33,000 CFM

- Spray temperature 55 to 90

- Bake temperature 90 to 160

- 2 - 3ph/1ph Intake Motor

Specifications

- V-bank filter section with 2” Pre-filters PB1000SLP

- Control panel Control spray and cure temperature.

- Single speed, spray and bake operation

- Electrical spec: Variable frequency drive -VFDs- and the exhaust and the intake

- Blower Type: Backward Incline Belt Drive Less Drive Package

All paint spray booths manufactured by RGI Mfg. Co. (RGI) are warranted by RGI, against defects in workmanship for materials under normal use for one year after the date of purchase from RGI. Any part which is determined by RGI to be defective in material or workmanship and is returned to RGI, shipping cost prepaid, will be, as the exclusive remedy, repaired or replaced at RGI’s option.

LIMITATIONS OF LIABILITY

Any liability of consequential and incidental damages is expressly disclaimed. RGI’s liability in all events is limited to, and shall not exceed, the replacement price of the part.

PRODUCT SUITABILITY

All states and localities have codes and regulations governing the construction, installation and/or use of paint spray booths, which may be interpreted differently from those in neighboring areas. While RGI attempts to assure that it’s spray booths comply with such codes, it cannot guarantee compliance, and cannot be responsible for how the spraybooth is installed or used. Before the purchase and use of a spray booth, please review the spray booth application, and national and local codes and regulations, and be sure that the product, installation and use comply with them.

FREIGHT LOSS OR DAMAGE POLICY

Unless otherwise specified, RGI accepts no responsibility for loss or damages to products shipped from RGI unless said products are shipped freight prepaid by RGI. Exception: If it is determined by RGI that loss or damage occurred as a result of negligence on the part of RGI, RGI will replace the lost or damaged articles. If such a determination is made by RGI, replacement of lost or damaged articles will occur only after receipt of a written request, from the purchaser.