Omer Lifts Fox 65 14,000 Lbs Capacity Alignment Double Scissor Lift

The Fox 65 service and alignment rack is designed with a minimal footprint, extending the use of the shop floor and giving uninhibited vehicle access for the operators.

The platform runways are rigid and built to resist deflection regardless to vehicle's wheelbase or weight distribution; this translates in precise alignment readings. Thanks to its innovative master/double slave hydraulic system, the synchronization between runways is granted with the greatest precision. The pivot points are manufactured for longevity, incorporating an anti-rotation system, self-lubricating bushings, and zerk grease fittings, all designed to increase longevity and allow for years of trouble free operation. The drive-on ramps remain attached to the platforms when the lift leaves the ground, maximizing the shop floor. Their length allows even the lower-profile vehicles to get on the lift.

The Fox 65 is ALI Certified and built to the highest safety standards. Multiple safeties are built within the system including parachute valves, mechanical safety devices, automatic insertion, photocells to control the synchronization of the runways, micro-switch with an acoustic buzzer to complete the lowering process, low voltage controls (24v), and “deadman” controls.

A hot-dipped galvanization of the whole structure of this lift can be added as an option, offering extra protection from corrosion due to water or salt exposure, and dramatically extending the life of the equipment.

Features

- Built to a higher standard of quality; made in Italy by O.ME.R S.p.A., a world leader in Lift Manufacturing for over 40 years in an ISO 9001 facility.

- Incorporating a minimal footprint, extending the use of the shop oor and giving uninhibited vehicle access for the operators.

- Platform Runways are rigid and built to resist de ection regardless to vehicles wheelbase or weight distribution – this translates in precise alignment readings.

- Thanks to the innovative master/double slave hydraulic system, synchronization between runways is granted with the greatest precision.

- The drive-on ramps remain attached to the platforms when the lift leaves the ground, maximizing the shop floor. Their length allows even the lower vehicles to get on the lift.

- The pivots points are manufactured for longevity, incorporating an anti-rotation system, self-lubricating bushings and zerk grease fittings.

- ALI Certified and built to the highest safety standards.

- Multiple Safeties within the system including parachute valves, mechanical safety devices, automatic insertion, photocells to control the synchronization of the runways, microswitch with an acoustic buzzer to complete the lowering process, low voltage controls (24v), and “deadman” controls.

- Hot-dipped galvanization of the whole structure as an option, offering extra protection from corrosion due to water or salt exposure, and dramatically extending the life of the equipment.

Specifications

| Capacity | 14,000 LB. / 6.5T |

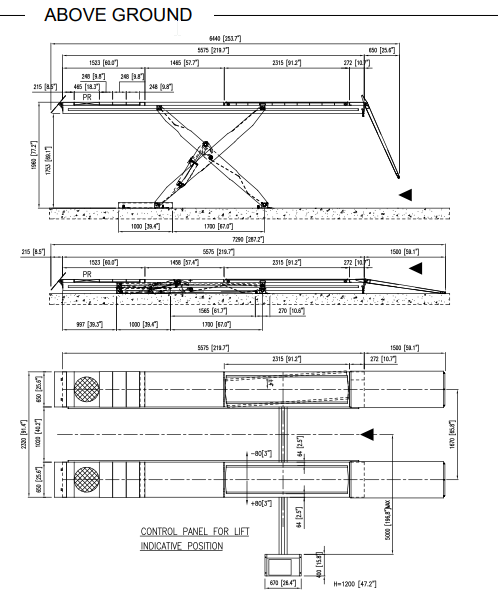

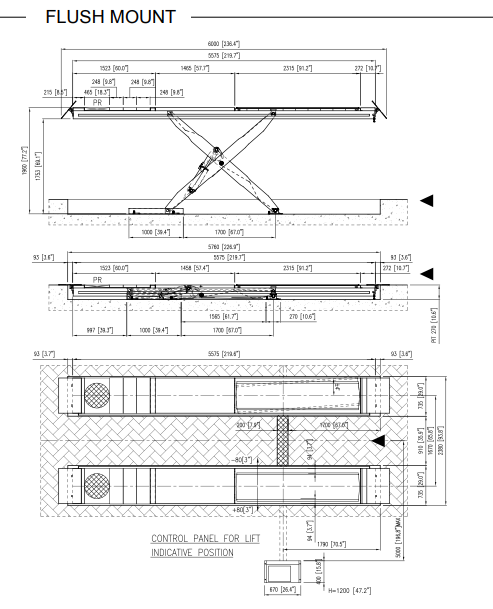

| Overall Platform Length | 219.7" / 5575 mm |

| Platform Width | 25.6" / 650 mm |

| Collapsed Height | 10.4" / 265 mm |

| Raised Height | 77.2" / 1960 mm |

| Overall Length (Surface Mounted) | 287.2" / 7290 mm |

| Length of Rear Slip Plates | 89.4" / 2270 mm |

| Maximum Service Wheel Base | 185 " / 4700 mm |

| Maximum Wheelbase for 4 wheel alignment | 185 " / 4700 mm |

| Noise Level | < 75 decibels |

| Power Requirement | 2.2 Kw 220 V / 1 phase |

| Shipping Weight | 6170 lbs / 2800 kg |

Optional Accessories (*Sold separately)

- Hot-Dipped Galvanization for wet environments.

- Air operated Turning Plates.

- Extended length runway.

- Rolling Jacks.

- Rear Pneumatic Slip Plates.

- 3-phase power supply.

Downloads

Limited Warranty

OMER USA, Inc. lifts are guaranteed to the original owner. OMER USA shall repair or replace, at OMER’s discretion, for the full warranty period, those parts that prove upon inspection to be defective, and pay for reasonable costs of transportation and/or labor for replacement of said parts for the warranty period stated below. This warranty shall not apply unless the product is installed, used, and maintained according to OMER’s specifications set for in OMER’s Installation, Operation and Maintenance Manuals. Use of any unapproved parts or accessories will void your warranty. This limited warranty extends only to the original purchaser and is not transferable.

This warranty does not cover normal maintenance or adjustments, damage or malfunction caused by improper handling, installation, abuse, misuse, negligence, carelessness of operation, or normal wear and tear. In addition, this warranty does not cover equipment when repairs have been made by anyone other than a service technician that has been approved in writing by the OMER Service Department.

This warranty is exclusive and is in lieu of all other warranties expressed or implied including any implied warranty of fitness for a particular purpose, which implied warranties are expressly excluded. No employee, agent, representative, dealer, or other person or entity is authorized to give any warranties of any nature on behalf of OMER USA, Inc.

The remedies described are exclusive and in no event shall OMER USA, Inc. be liable for special, consequential or incidental damages for the breach of or delay in performance of the warranty.

General Warranty Policy for all OMER USA Products:

- 1. Parts: 24 Months

- 2. Labor: 12 Months

General Warranty Terms and Conditions:

- 1. Warranty will commence from the date of the initial invoice.

- 2. OMER USA, Inc. will cover the most cost-effective shipping option for warranty items. If a customer shall request that a part be shipped by a more expeditious method, the difference in cost shall be covered by said customer.

- 3. Warranty does not apply in cases where equipment has been damaged due to improper storage, improper use, uneven loading, accident (including transportation), modifications, or any other causes which are not the result of defective materials or workmanship. Please refer to the product manuals (and ALI documentation where it applies) included in the scope of delivery with every product.

- 4. Warranty claims MUST be submitted via email or fax, and must include a detailed description of the issue that initially incited the claim, in addition to photographic evidence of the part in question.

- 5. All warranty service work requires written approval by an authorized OMER USA, Inc. representative (Service Manager, Sales Manager, or General Manager) prior to starting any work, travel, etc. Without prior approval, any warranty work expenses will be declined. compensation.

- 6. A completed “Service Itinerary Report” with customer signature needs to be submitted to OMER USA with each Service Expense Report within five (5) working days after completing the work. Failure to comply with these policies may result in non-reimbursement for such work.

Rates and Conditions for Reimbursable Warranty Service Work

- 1. Cost of initial service call: $95.00

Note: Initial service call includes the first one hour of on-site service and up to 50 miles of travel.

- 2. Additional hourly rate on site: $75.00

- 3. Hourly rate for travel only: $50.00

- 4. Per mile reimbursement over 50 miles: $0.60/mile

- 5. Other Expenses:

Any additional service expenses incurred for travel other than those noted above require prior approval and will be arranged by OMER USA. This includes, but is not limited to airline ticks, hotel rooms, and rental car usage.